The smaller the radiuses of bend the smaller the springback. Springback will cause the tube to unbend from two to ten degrees depending on the radius of bend, and may increase the bend radius of the tube.

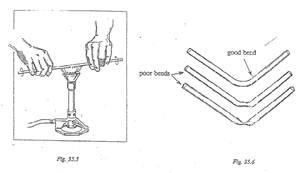

“Springback” is the term used to describe the tendency of metal that has been formed to return to its original shape. This should be considered when selecting a bend die. The pressure die forces the tube into the bend die.įigure 3 Control of Springback Springback is excessive when a mandrel is not used. The clamp die holds the tube in position while bending. The bend die helps to prevent the tube from flattening and forms a given radius of bend. Basic Primary Tooling A bend die, clamp die, and pressure die are the minimum essentials for bending tube. The forces acting on the tube also becomes greater as the radius of the bend becomes smaller. If the wall thickness of the tube is decreased, it also becomes weaker. As the size of the tube diameter is increased, the tube becomes weaker. Two factors that help prevent this from happening are a grooved bend die, which supports the tube along the centerline and the natural strength of the tube round or square (Figure 2).įigure 2 Little or no support is needed within the tube when the tube diameter is small and the wall is thick. The outside and inside of the bend tend to pull towards the centerline of the tube (flattening). Excessive flattening or wrinkling of the bend should not occur. Compressedįunction of Bend Die When the ratio of the tube diameter to wall thickness is small enough, the tube can be bent on a relatively small radius (Centerline Radius or CLR = 4 x Tube O.D.). The material that forms the outside of the bend has further to travel and therefore is stretched the inside of the bend has less distance to travel and is compressed. The material actually is formed approximately about the centerline of the tube. The outside wall is reduced in thickness due to the stretching of the material and the inside wall becomes thicker due to the compressing of the material (Figure 1). Stretching and Compression Principles When a tube is bent, two things happen to metal (Figure 1-a). TROUBLESHOOTING Tube breakage Tube wrinkling Scratches/Marking on Tube Centerline Tube Collapses Either With or Without Wrinkling Through Bend Hump at the End of a Bend and Mandrel Ball Humps Tool Marks/Scratches Excessive Springback Possible Reasons for Link Failure Final Tips V. BENDING WITH BALL MANDREL AND WIPER DIE Bending Thin Wall Tubing IV. BENDING TUBE WITH A PLUG MANDREL Balanced Pressures Unbalanced Pressures Mandrel Too Far Back Mandrel Too Far Forward III. BENDING TUBE WITHOUT A MANDREL Stretching and Compression Principles Function of Bend Die Basic Primary Tooling Control of Springback Kinked or Buckled Bends II. The information applies to steel with a maximum tensile strength of Rm=400N/mm2.ĭeviating data applies to profiles produced from aluminium, stainless steel or high-strength materials.BASIC TUBE BENDING GUIDE 2710 Swamp Cabbage Court ٠ Fort Myers, FL 33901 23 ٠ 23 fax ٠ 80 US & Canada ٠email: Other profile forms, dimensions and special profiles are possible at any time The table only contains a brief extract of the possible profiles and dimensions.

PLASTIC TUBE BENDING SERIAL

Fully automatic NC-controlled tube bending machines offer many of the advantages of CNC-controlled machines with considerably lower investment costs.įully automatic NC-controlled tube bending machines are used in single part and serial manufacturing, in workshop operations and production.ĪPPLICATIONS AREAS: Metal construction, metalwork and general machine construction, pipework construction, hydraulics, plant constructionġ2×9 cm display and program administrationĭirectly on the machine or optionally on an All clamping functions and drives operate hydraulically.

Bending programs can be created directly on the machine or optionally on an external Notebook and transferred online to the machine control (PP41).įully automatic NC-controlled tube bending machines guarantee efficient production of one-off and serial parts.

PLASTIC TUBE BENDING MANUAL

Manual adjustment of the length and angle stops for the tube feeding and turning is unnecessary. tube intake, bending and tube turning, takes place automatically and through program control. Fully automatic tube bending machines NC it doesn’t always have to be CNCįully automatic NC-controlled tube bending machines are equipped with three individually driven and controlled axes.

0 kommentar(er)

0 kommentar(er)